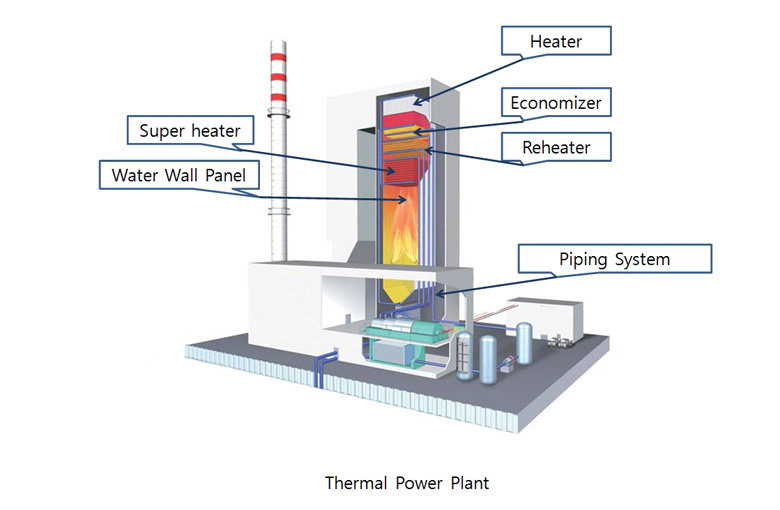

Thermal Power Generation Facility Materials

Home > Products & Service > Thermal Power Generation Facility Materials > Boiler & BOP Tubes

Boiler & BOP Tubes

Coal Fired Power Plant

Oil Fired Power Plant

CFB Boiler

IGCC ( Integrated Gasification Combined Cycle )

CCPP ( Combined Cycle Power Plant ) / HRSG ( Heat Recovery Steam Generator )

Carbon & Alloy Seamless tubes and pipes

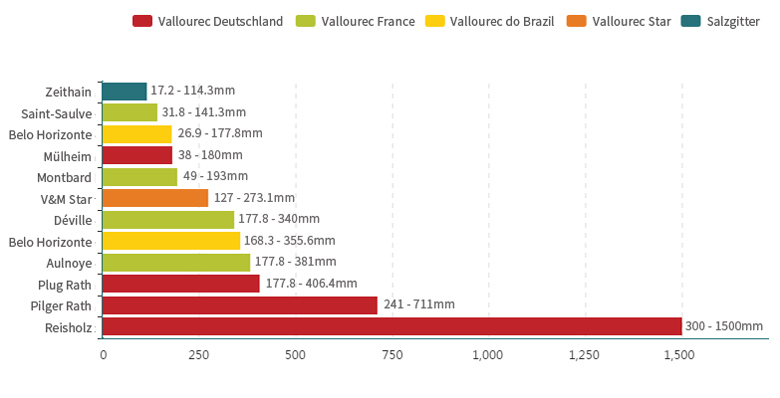

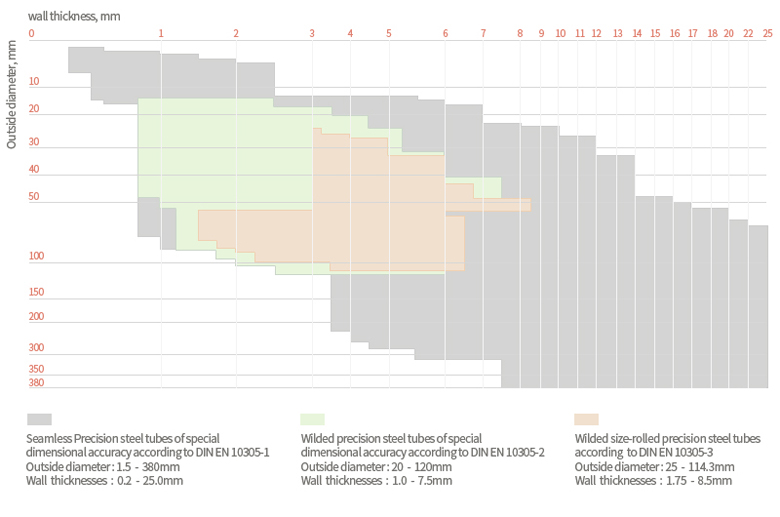

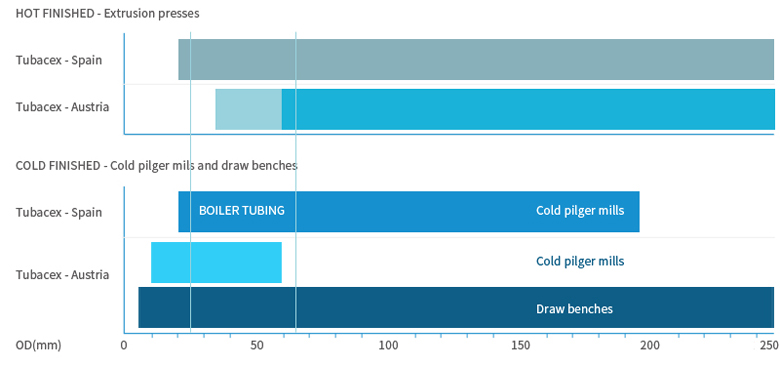

Product range, mill by mill

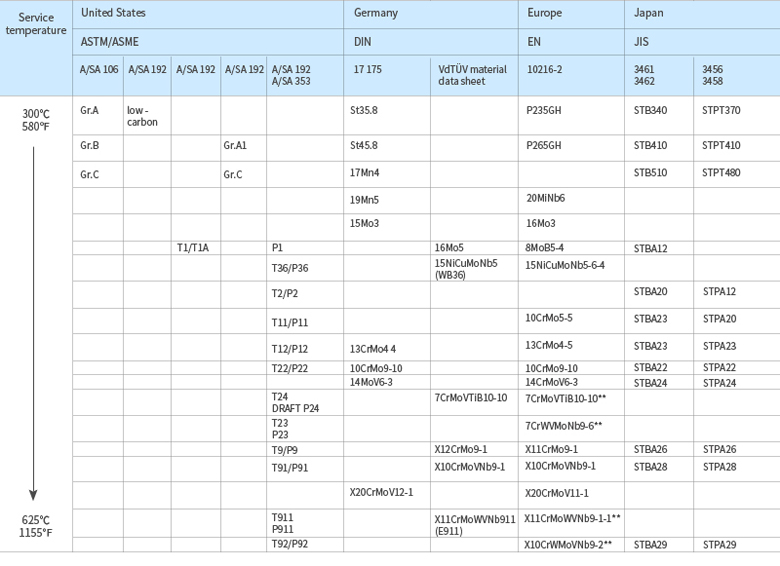

Product material

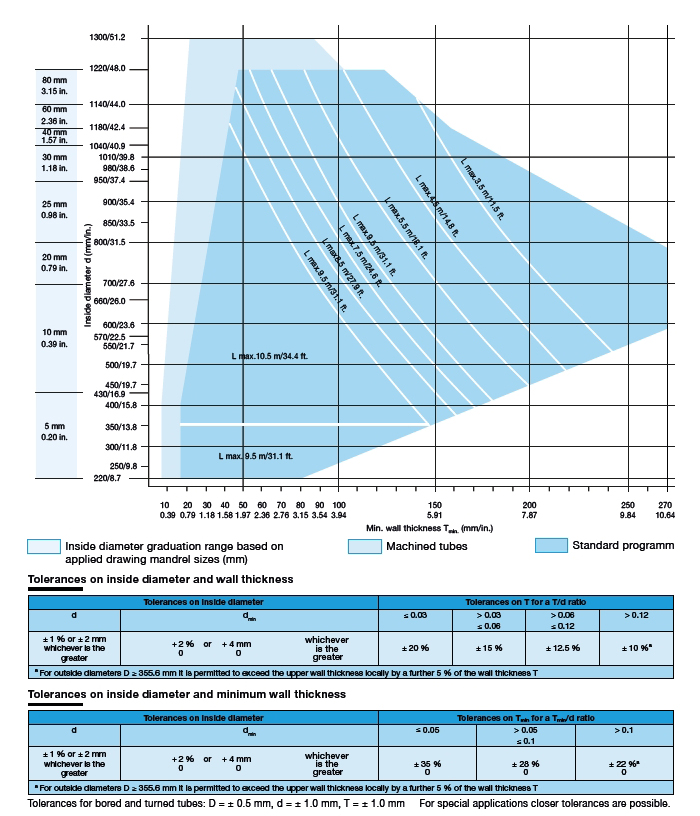

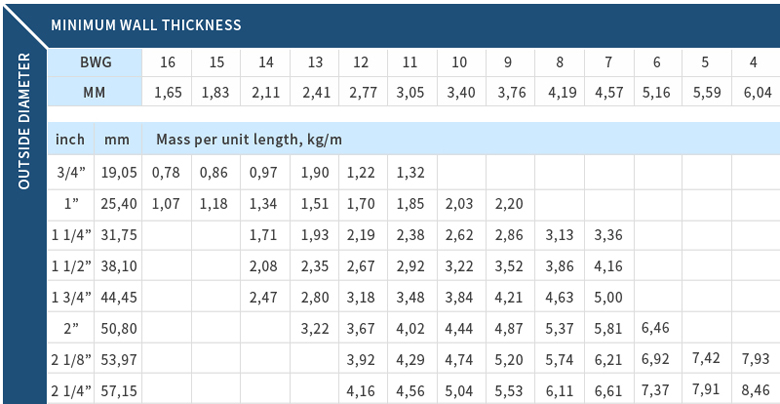

Manufacturing program for inside-diameter-controlled pipe

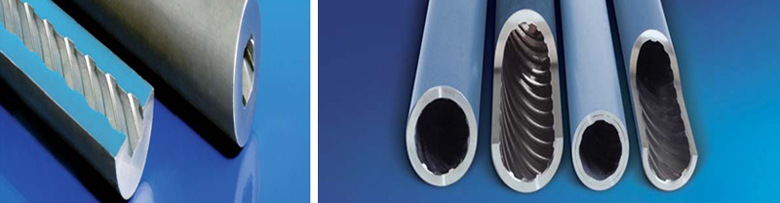

Carbon & Alloy Seamless rifled tubes

Product range

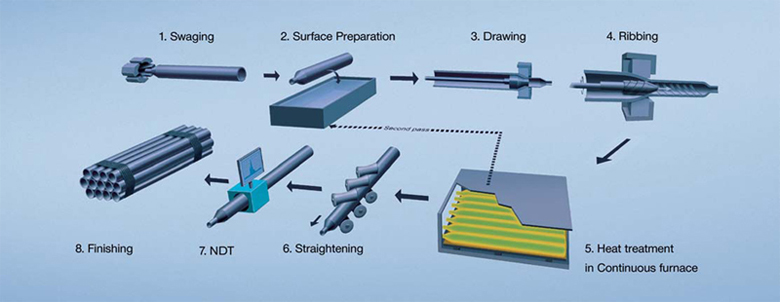

Manufacturing process

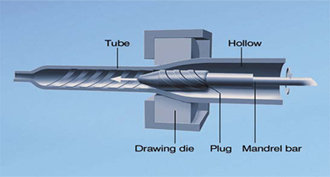

Ribbing process

Ribs are obtained through cold drawing process on a grooved plug from hollows supplied by SMP mills. After drawing and ribbing pass, tubes are heat treated to get specified metallurgical requirements. Before final cutting, tubes are 100% checked by Eddy Current and/or Ultrasonic test, depending on customer’s requirements.

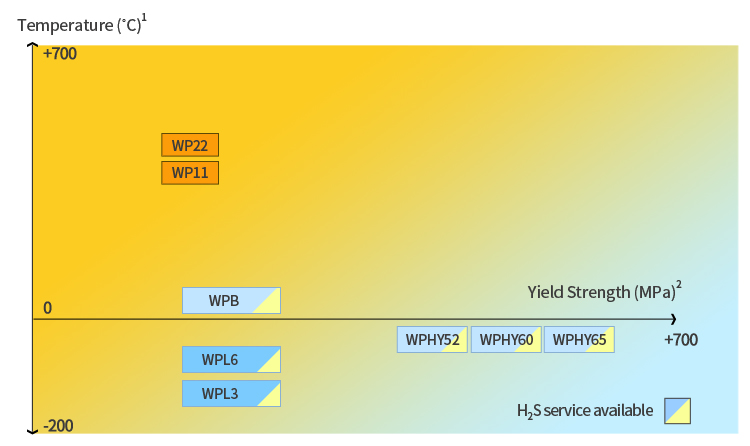

Product material

| Steel | Standard | Grade |

|---|---|---|

| Carbon | ASTM A 106 | Grade A, B |

| ASTM A 210 | Grade A1, C | |

| EN 10216-2 | P235GH, P265 GH | |

| Alloy | ASTM A 209 | T1, T1A |

| ASTM A 213 | T2, T11, T12, T22, T23 | |

| EN 10216-2 | 16Mo3, 13CrMo4-5, 10CrMo9-10 | |

| ※ Other grades and standards may be available upon request. | ||

Stainless Seamless tubes

Size Ranges of the Mills

Seamless Stainless Tubes

Tolerances to ASTM/ASME A 1016

Grades and Equivalencles

| Equivalent grades according to international standards | |||||

|---|---|---|---|---|---|

| ASTM/ASME A/SA213 |

EN 1016-5 EN 10297-2 | UNS | Code Case |

VdTUV | |

| TP304H | X6CrNi18-10 | 1.4948 | S30409 | ||

| TP310H | X8Cr-Ni25-21 | 1.4845 | S31009 | ||

| TP321H | X8CrNiTi18-10 | 1.4541 1.4878 1.4940 |

S32109 | ||

| TP347/347H | X6CrNiNb18-10 | 1.4550 1.4912 |

S34700 S34709 |

||

| TP316H | X6CrNiMoB17-12-2 | 1.4919 | S31609 | ||

| TX304HB* | X10CrNiCuNb18-9-3 | 1.4907 | S30432 | 2328 | 550 |

| TUBACEX 347HFG* |

X8CrNi19-11 | 1.4908 | S34710 | 547 | |

| TP310HCbN** | X6CrNiNbN25-20 | 1.4952 | S31042 | 2115 | 546 |

| *TUBACEX steel name. **Under development. Cusom materials available upon request. | |||||

Mechanical properties and temperatures

| Mechanical properties by steel grade | |||||

|---|---|---|---|---|---|

| ASTM/ASME A/SA213 |

Working temperature (℃[℉])) |

Yield strength (min. MPa) |

Tensile strength (min. MPa) |

Elongation (min. %) |

Hardness (max. Rockwell)) |

| TP304H | 590[1095] | 205 | 515 | 35 | 90HRB |

| TP310H | 590[1095] | 205 | 515 | 35 | 90HRB |

| TP321H | 600[1110] | 205 | 515 | 35 | 90HRB |

| TP347/347H | 610[1130] | 205 | 515 | 35 | 90HRB |

| TP316H | 610[1130] | 205 | 515 | 35 | 90HRB |

| TX304HB* | 650[1200] | 235 | 590 | 35 | 90HRB |

| TUBACEX 347HFG* |

650[1200] | 205 | 550 | 35 | 90HRB |

| TP310HCbN** | 670[1240] | 0 | |||

| *TUBACEX steel name. **Under development. | |||||

Carbon & Alloy tubes and pipes for Elbows, Tees, Reducers and caps.

Our dimensional Range

New Products & Services for more Value

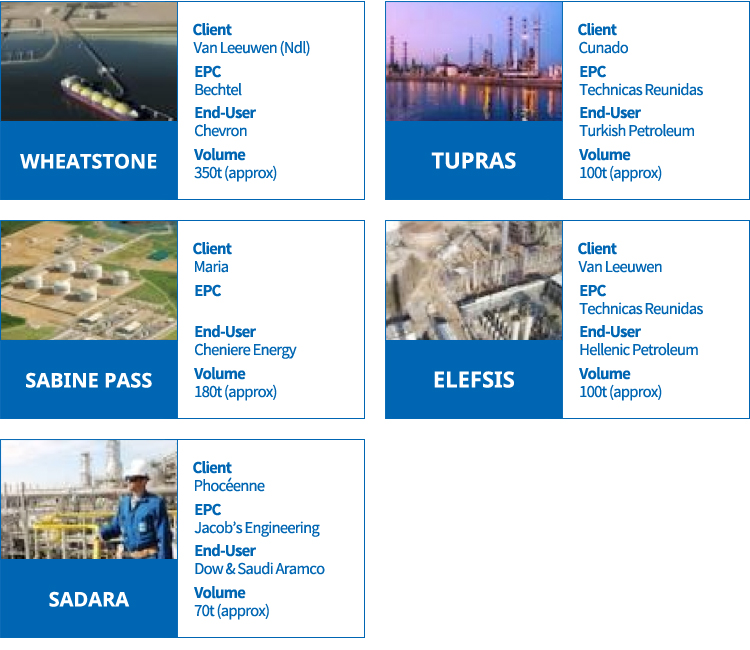

Some of our Partnership in Projects